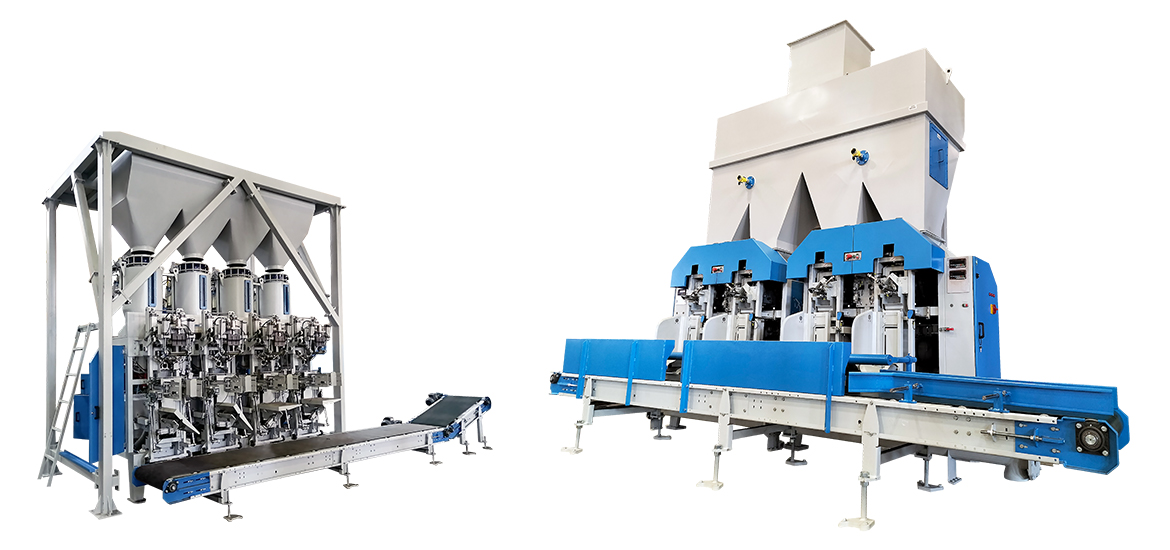

VALVE BAG FILLING

INLINE PACKING

-

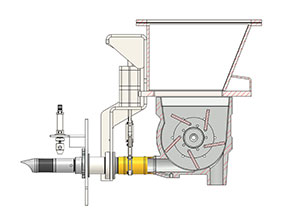

IMPELLER TYPE VALVE BAG FILLING MACHINE

Offers the most suitable solution for packaging fine and ground products with medium and high densities and fluidity.

The product in the machine reservoir is filled in to bag with 4 blade turbine driving and air support.

Models with single, dual, triple and quad filling spouts are available according to capacity requirements. Machine filling speed varies according to the density and fluidity of the product.

Suitable for: Cement, cement sand, Soda Ash (Na₂CO₃), chemical mixtures, joint filler, gypsum, plaster, barite, miscellaneous chemicals

Thanks to electronic weighing system and double speed filling [coarse and fine feature, that ensures constant and high accurancy filling rates. Depends on capacity request 1-2-3-4 spouts linear type models are available.

-

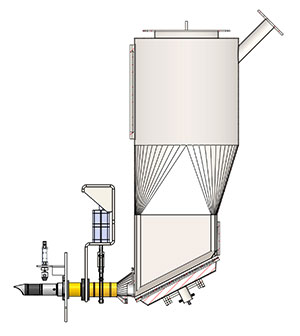

AIR TYPE VALVE BAG FILLING MACHINE

Offers the most suitable solution for packaging granules, powder, fine powder, and grout products with medium and high densities.

The upper valve of the filling chamber is closed once the product is filled up to the level sensor in filling chamber. Then, the product in the filling chamber is fluidized with air and filled into bags with the help of low pressure air supplied from the top.

Models with single, dual, triple and quad filling spouts are available according to capacity requirements.

Performs precision weighing with electronic, load-cell weighing units, and fast-slow filling systems. The air type bag packaging machine operates according to gross weighing principle and performs weighing during the filling process.

VALVE BAG FILLING General Features

- Bag Type: (kraft, PE, PP, v.s.)

- Bags/Hour Capacity: 150 - 1200

- Filling Weight: 10 - 50 KG