STRETCH HOODER

Stretch Hood Machines

Our stretch hood machines are perfectly implemented for a wide variety of industries such as chemicals, minings, ceramics, minerals, beverages, food, feed, seeds , etc.

Varlık Makina is your complete solution partner from single source for all your palletising and stretching needs

Just a few of our references...

We continue to work with our STRETCH HOOD machines in dozens of different plants in many parts of the world.

STRETCH HOOD GALLERY

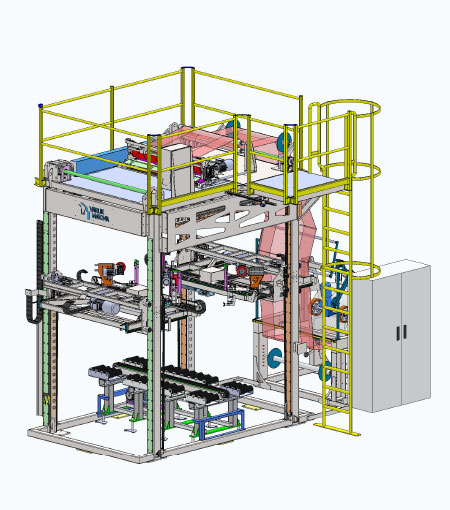

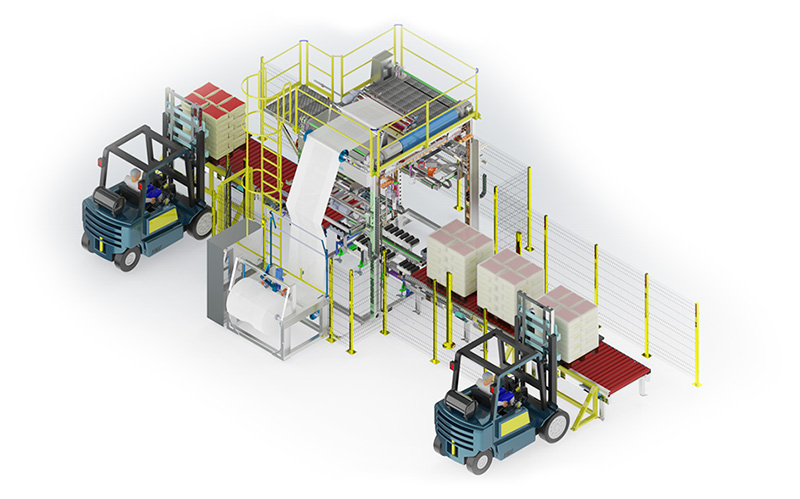

how it works

Would you like to learn step by step working principle of our Stretch Hood Machines?

01

Pallet inlet

Feeding Conveyor

It allows safely external pallet feeding by using safety light sensor barriers

02

Film Measuring,

Sealing and Cutting

Pallet height is measured with the help of sensors. According to the pallet height, the length of the nylon is automatically cut and sealed.

03

Stretching

Stretch film is held by the arms on the machine. According to the pallet width, the arms are opened and the nylon film is stretched.

04

Pallet Output and Stock

After the pallet stretching process is finished, the machine returns to its starting position. The stretched pallet is transported to the exit conveyor and stored and ready to be taken by forklift

“Varlık Makina is your complete solution partner from single source for all your End Of Line Solutions”

HOW DOES STRETCHING WORK?

Let's take a look at how we do stretching step by step.

-

01

Unwinding of stretch hood film roller and opening from coil

-

02

Cutting according to pallet size automatically and sealing for each pallet

-

03

Hood formed by Arms and Ready to be stretched

-

04

Cartesian Arms , Stretch the film and it generates plastic elasticity forces in all directions

-

05

Cartesian Arms Moves from up to down and it adds vertical stretch forces for great load stability

-

06

Stretching Process Finish, Available for different Pallet sizes

Why should I Choose stretch hooder instead of stretch wrapping and stretch shrink ?

It gives you extra advantages such as below ; -Faster Stretching Speed -Increased Productivity -Savings in consumables and energy -Protection against external agents, such as , Rain, dust, UV , -Better packaging quality -Higher speed in pallet packaging -Greater process safety

FEATURES

Advance Technology for Stretching...